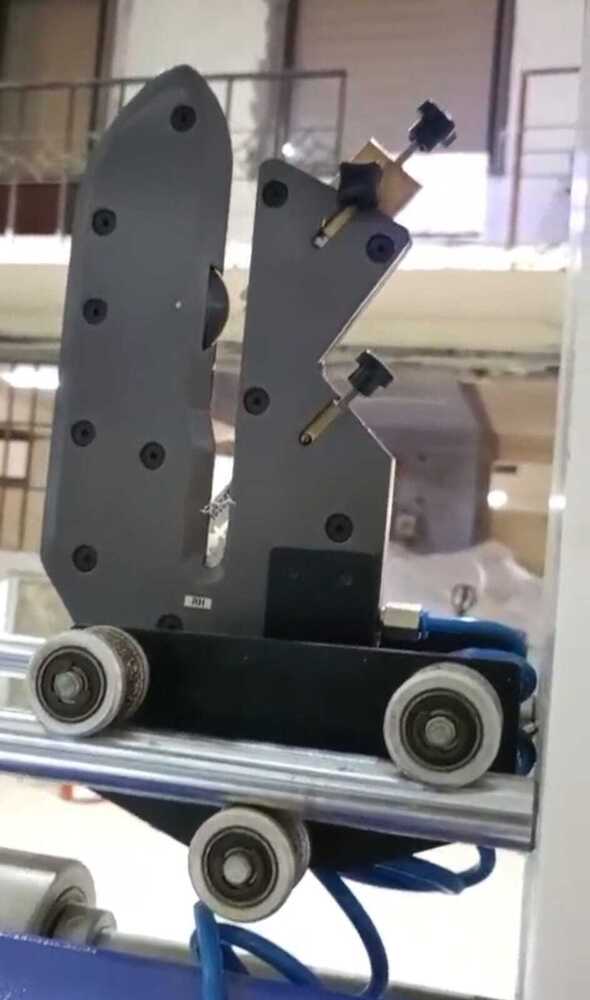

Surface winder

MOQ : 1 Unit

Surface winder Specification

- Computerized

- Yes

- Automatic Grade

- Semi-Automatic

- Control System

- PLC Control

- Drive Type

- Direct

- Power

- 5 Horsepower (HP)

- Weight (kg)

- 2.5 Metric Ton

About Surface winder

Find the unrivaled efficiency of our Surface Winderan unassailable choice for high-performance winding applications. Customizable to meet your unique requirements, this must-have machine features semi-automatic operation, PLC control system, and direct drive. With potent 5 HP power and a robust weight of 2.5 metric tons, it delivers consistent and precise results for diverse industries. Computerized controls ensure optimal productivity and reliability. Proudly manufactured and supplied in India, the Surface Winder is engineered for lasting durability and seamless integration into advanced production environments.

Versatile Usage and Applications of Surface Winder

The Surface Winder is engineered for extensive usage in industries requiring roll winding, such as textiles, packaging, or paper production. These units are used for winding materials into tight, uniform rolls, ensuring consistent quality and reduced material wastage. Designed for application in factories, workshops, and large-scale manufacturing plants, the Surface Winder supports streamlined processes and enhances operational efficiency wherever reliable roll handling is essential.

Export Markets, Samples, and Delivery Information

Our Surface Winder enjoys robust export demand in major markets, including Asia, Africa, and the Middle East. Organizations can request sample policies and product demonstrations. The asking price and sale price are competitive, reflecting our commitment to value and quality. Dispatching of orders is prompt, typically within a standard delivery time as mutually agreed after confirmation, ensuring swift deployment and minimal wait for buyers.

Versatile Usage and Applications of Surface Winder

The Surface Winder is engineered for extensive usage in industries requiring roll winding, such as textiles, packaging, or paper production. These units are used for winding materials into tight, uniform rolls, ensuring consistent quality and reduced material wastage. Designed for application in factories, workshops, and large-scale manufacturing plants, the Surface Winder supports streamlined processes and enhances operational efficiency wherever reliable roll handling is essential.

Export Markets, Samples, and Delivery Information

Our Surface Winder enjoys robust export demand in major markets, including Asia, Africa, and the Middle East. Organizations can request sample policies and product demonstrations. The asking price and sale price are competitive, reflecting our commitment to value and quality. Dispatching of orders is prompt, typically within a standard delivery time as mutually agreed after confirmation, ensuring swift deployment and minimal wait for buyers.

FAQs of Surface winder:

Q: How does the PLC Control System enhance the operation of the Surface Winder?

A: The PLC Control System provides precise management of winding parameters, allowing for efficient, consistent, and automated operation with minimal supervision required.Q: What applications is the Surface Winder suitable for?

A: The Surface Winder is ideal for industries such as textiles, packaging, and paper manufacturing, where high-quality roll winding is crucial.Q: When can I expect delivery after placing an order for the Surface Winder?

A: Delivery times are negotiated at the time of purchase, with prompt dispatching arranged upon order confirmation to ensure timely receipt.Q: Where can the Surface Winder be installed for optimal performance?

A: The Surface Winder is designed for installation in factories, workshops, and manufacturing plants where stringent roll control and reliability are needed.Q: What is the process for requesting a sample or price quotation?

A: Interested buyers can contact our sales department for details about sample policies and to obtain an accurate asking price or sale price based on requirements.Q: What benefits does the Surface Winder offer over conventional winders?

A: Its semi-automatic, computerized system provides unrivaled performance, reduced wastage, superior control, and ease of integration into existing production workflows.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Plastic Recycling Machine Category

Plastic Granules Mixture Machine

Minimum Order Quantity : 1 Piece

Control System : PLC Control

Automatic Grade : SemiAutomatic

Warranty : Yes

Screw Barrel

Price 250000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Human Machine Interface

Automatic Grade : Manual

Warranty : 1 year

Computerized : No

Losa Cutter

Minimum Order Quantity : 1 Piece

Control System : PLC Control

Automatic Grade : SemiAutomatic

Warranty : Yes

Plastic granulator machine

Minimum Order Quantity : 1 Unit

Control System : Human Machine Interface

Automatic Grade : Manual

Warranty : 1 Year

Computerized : No

Send Inquiry

Send Inquiry